August 16, 2019

50 years of Leonhard Fischer

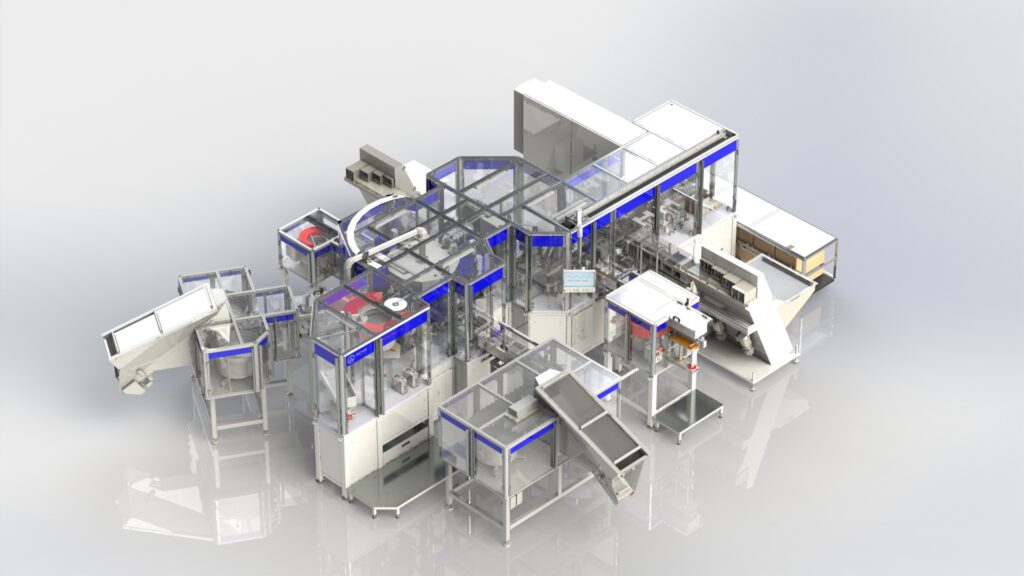

2019 is proving to be a year of milestones at LINDAL. As well as our 60th anniversary we are also celebrating 50 years since our manufacturing technology company, Leonhard Fischer was founded.

To commemorate the five decades of achievement with Leonhard Fischer, we wanted to unveil some of the secrets to our success, showing how Fischer has made it from machine maintenance shop to provider of Excellence in Machine and Mould technology.

Established in 1969, Fischer is a fully integrated and project managed solution for tools, equipment, automation and manufacturing conversion. It has grown because of its commitment to several core values based on its unrivalled experience, a scrupulous approach to every single project and a sharp long-term vision.

Planning

Fastidious planning and preparation are at the centre of what Fischer does. The early stages are a key part of the product design phase and as such, we make sure from the start that the right technical equipment experts are involved in every project, and that every minute detail is considered in the whole manufacturing process.

Expertise

We have extensive mould tool design and manufacturing expertise which has been developed over 50 years; knowing exactly what tool specifications and capabilities are required gives us a huge advantage and appeal to our customers.

Flexibility

Our attitude is to listen, understand and implement and this means we need to be flexible in our approach. To get the right solution, we can either build the tools ourselves or work with external toolmakers, depending on the project. Whichever direction we take, our expertise again plays a critical role, as we know exactly how to specify tool requirements to external manufacturers.

Thinking ahead with LINDAL’s vision

Our industry dictates that we cannot afford to sit still, we must always be looking to the future. The latest generation of machines being developed at Fischer are being prepared for industry 4.0 capabilities, which is in line with LINDAL Group’s long-term vision to provide manufacturing excellence through ‘best in class’ manufacturing practices.

Jonathan Read, Group Technology Director: “Our 50 years’ experience in the design, development and manufacture of high speed automated assembly equipment helps us deliver the most complex of projects on budget and on time and we intend to keep on doing what we do so well.”