Hamburg, Germany – July 21st, 2021

Global aerosol dispensing company, LINDAL Group has introduced an advanced spray imaging system to help deliver new levels of spray performance insight for customers.

Global aerosol dispensing company, LINDAL Group has introduced an advanced spray imaging system to help deliver new levels of spray performance insight for customers.

As market-leading dispensing experts, LINDAL already conduct detailed spray analysis in the form of flow, particle size, spray angle/shape and spray pattern performance on their standard product range, as well as the bespoke solutions they work on with their innovation partners. The new technology not only adds to this, but provides a new avenue for in-depth consumer tests, with additional spray characterisations, including the measurement of shape and velocity also planned for the future utilisation of the technology.

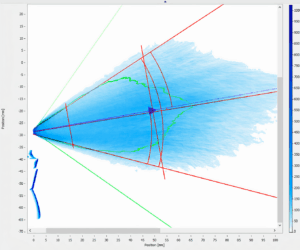

The new measurement technology, deployed at LINDAL’s Global Innovation Centre in France, uses optical techniques to capture spray behaviour at high speed (around 7500 images per second). Comprising of front and back radial lighting, camera and suction system hardware, its integrated software produces 30 second videos of spray movement for analysis, equivalent to 0.1 seconds in real time. The process provides detailed information on axial plume spray, including the particle distribution as well as the angle, diameter and length.

Eric Lambine, Central Laboratory Manager at LINDAL’s GIC, said: “The software’s ability to capture the behaviour of the spray and not simply the size of spray particles, is crucial. This information allows us to understand so much more about spray patterns and performance, which creates far greater objectivity to our analyses and discussions. We believe it will significantly benefit our customers that we are working with now and in the future.”

The company believes the spray imaging system will also be effective when testing compressed air dispensing solutions. Spray performance can be affected due to a reduction of pressure over the lifecycle of the can, resulting in a larger droplet sizes and a ‘wet’ final product, not suitable for products such as hairsprays and deodorants.

With the production of more in-depth spray performance data, LINDAL plans to use the technology with compressed air systems to greater understand the performance of the product in association with the valve and actuator combination, over the lifecycle of a can.

Eric says: “We aim to generate a template incorporating an optimum propellant, valve and actuator combination, as well as deriving further quantitative data, producing new levels of quality in all our dispensing systems. Our ultimate goal is to give our customers the best opportunity to provide an improved consumer experience.”

About LINDAL Group

LINDAL Group is a worldwide leader in the design, manufacture and sale of valves, actuators and spray caps used in aerosol products. The Hamburg, Germany-based company has more than 60 years of experience with innovative dispensing solutions for the cosmetics, household, pharmaceuticals, food and technical industries.

The LINDAL Group is represented by subsidiaries and licensees in more than 15 countries throughout Europe, Asia and The Americas. The company is renowned for its innovative designs, which deliver optimal functionality and return on investment. As a result, LINDAL packaging solutions are the choice of the world’s most prestigious and trusted brands.

For more information, please contact: marketing@lindalgroup.com.